| Specification |

Commentary |

Grade |

Types |

UNS No. |

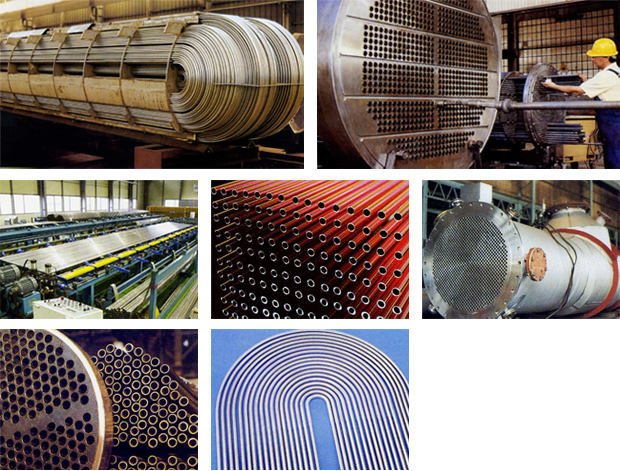

| A 213 |

Seamless Ferritic and Austenitic Alloy-Steel Boiler,

Superheater, and Heat-Exchanger Tubes |

TP 304 |

Seamless |

S30400 |

| TP 304L |

Seamless |

S31403 |

| TP 310 |

Seamless |

S31000 |

| TP 316 |

Seamless |

S31600 |

| TP 316L |

Seamless |

S31603 |

| TP 321 |

Seamless |

S32100 |

| TP 347 |

Seamless |

S34700 |

| A 249 |

Welded Austenitic Steel Boiler Superheater,

Heat Exchanger and Condenser Tubes |

TP 304 |

Welded |

S30400 |

| TP 304L |

Welded |

S31403 |

| TP 310 |

Welded |

S31000 |

| TP 316 |

Welded |

S31600 |

| TP 316L |

Welded |

S31603 |

| TP 321 |

Welded |

S32100 |

| TP 347 |

Welded |

S34700 |

|

| |

| |

|

|

| |

| |

Chemical Composition Chemical Composition |

| Classification |

Grade |

C |

Cr |

Ni |

Mo |

Others |

| KS(JIS) |

POSCO |

A

U

S

T

E

N

I

T

E |

301 |

301 |

≤0.15 |

16.0~18.0 |

6.00~8.00 |

- |

- |

| 301L |

301L |

≤0.03 |

16.0~18.0 |

6.00~8.00 |

- |

N ≤ 0.20 |

| 304 |

304 |

≤0.08 |

18.0~20.0 |

8.00~10.50 |

- |

- |

| 304J1 |

304J1 |

0.02~0.05 |

16.5~17.1 |

7.5~7.9 |

- |

Cu 1.9~2.2 |

| 304L |

304L |

≤0.03 |

18.0~20.0 |

9.00~13.00 |

- |

- |

| 304N1 |

304N1 |

≤0.08 |

18.0~20.0 |

7.00~10.50 |

- |

N 0.10~0.25 |

| 304N2 |

304N2 |

≤0.08 |

18.0~20.0 |

7.50~10.50 |

- |

Nb ≤ 0.15 |

| 305 |

305 |

≤0.12 |

17.0~19.0 |

10.5~13.0 |

- |

- |

| - |

305EG |

≤0.08 |

15.0~17.0 |

13.0~15.0 |

- |

- |

| 309S |

309S |

≤0.08 |

22.0~24.0 |

12.0~15.0 |

- |

- |

| 310S |

310S |

≤0.08 |

24.0~26.0 |

19.0~22.0 |

- |

- |

| 316 |

316 |

≤0.08 |

16.0~18.0 |

10.00~14.0 |

2.00~3.00 |

- |

| 316L |

316L |

≤0.03 |

16.0~18.0 |

12.00~16.0 |

2.00~3.00 |

- |

| 321 |

321 |

≤0.03 |

17.0~19.0 |

9.00~13.00 |

- |

Ti 5 X C% |

| XM15J1 |

XM15J1 |

≤0.08 |

15.0~20.0 |

11.5~15.0 |

- |

Si 3.5~5.0 |

| DUPLEX |

329J3L |

329J3L |

≤0.03 |

21.0~24.0 |

4.5~6.5 |

- |

N 0.08~2.0 |

F

E

R

R

I

R

E |

409 |

409 |

≤0.08 |

10.5~11.75 |

- |

- |

TI 6 X C%~0.75 |

| 409L |

409L |

≤0.03 |

10.5~11.75 |

- |

- |

TI 6 X C%~0.75 |

| 410L |

410L |

≤0.03 |

11.0~13.5 |

- |

- |

- |

| 430LX |

430LX |

≤0.03 |

16.0~19.0 |

- |

- |

Ti or Nb 0.1~1.0 |

| 430 |

430 |

≤0.12 |

16.0~18.0 |

- |

- |

- |

| 430Ti |

430Ti |

≤0.03 |

16.0~21.0 |

- |

- |

Ti 0.2~0.5 |

| 430J1L |

430J1L |

≤0.025 |

16.0~20.0 |

- |

- |

Nb 8 X (C%+n%)~0.8

Cu 0.30~0.80 |

| - |

439M |

≤0.03 |

18.0~19.0 |

- |

- |

Nb 0.3~1.0 |

| 436L |

436L |

≤0.025 |

16.0~19.0 |

- |

0.75~1.25 |

Ti, Nb, Zr

8 X (c%+N%)~0.8 |

| 444 |

444 |

≤0.025 |

17.0~20.0 |

- |

1.75~2.50 |

Ti, Nb, Zr

8 X (c%+N%)~0.8 |

| 445 |

445 |

≤0.015 |

21.0~23.0 |

- |

1.7~2.4 |

Ti ≤ 0.30 |

| - |

446M |

≤0.015 |

25.0~28.0 |

- |

- |

Ti ≤ 0.30 |

MARTEN

SITE |

410 |

410 |

≤0.015 |

11.5~13.5 |

- |

- |

- |

| 420J1 |

420J1 |

0.16~0.25 |

12.0~14.0 |

- |

- |

- |

| 420J2 |

420J2 |

0.26~0.4 |

12.0`14.0 |

- |

- |

- |

|

| |

Mechanical Properties Mechanical Properties |

| Classification |

Grade |

Heat Processing Conditions |

Internal Strength

(N/㎟) |

Tensile Strength

(N/㎟) |

Elongation Rate

(%) |

Hardness |

| KS(JIS) |

POSCO |

HB |

HRB |

HV |

A

U

S

T

E

N

I

T

E |

301 |

301 |

S |

≥205 |

≥515 |

≥40 |

≤207 |

≤95 |

≤218 |

| 301L |

301L |

S |

≥220 |

≥550 |

≥45 |

≤187 |

≤90 |

≤200 |

| 304 |

304 |

S |

≥205 |

≥515 |

≥40 |

≤197 |

≤90 |

≤200 |

| 304J1 |

304J1 |

S |

≥155 |

≥450 |

≥40 |

≤197 |

≤90 |

≤200 |

| 304L |

304L |

S |

≥170 |

≥485 |

≥40 |

≤218 |

≤90 |

≤200 |

| 304N1 |

304N1 |

S |

≥275 |

≥550 |

≥35 |

≤248 |

≤90 |

≤220 |

| 304N2 |

304N2 |

S |

≥345 |

≥690 |

≥35 |

≤187 |

≤100 |

≤260 |

| 305 |

305 |

S |

≥170 |

≥485 |

≥40 |

≤187 |

≤90 |

≤200 |

| - |

305EG |

S |

≥175 |

≥480 |

≥40 |

≤187 |

≤90 |

≤200 |

| 309S |

309S |

S |

≥205 |

≥515 |

≥40 |

≤187 |

≤90 |

≤200 |

| 310S |

310S |

S |

≥205 |

≥515 |

≥40 |

≤187 |

≤90 |

≤200 |

| 316 |

316 |

S |

≥205 |

≥515 |

≥40 |

≤187 |

≤90 |

≤200 |

| 316L |

316L |

S |

≥175 |

≥485 |

≥40 |

≤187 |

≤90 |

≤200 |

| 321 |

321 |

S |

≥205 |

≥515 |

≥40 |

≤187 |

≤90 |

≤200 |

| XM15J1 |

XM15J1 |

S |

≥205 |

≥520 |

≥40 |

≤207 |

≤95 |

≤218 |

| DUPLEX |

329J3L |

329J3L |

S |

≥450 |

≥620 |

≥18 |

≤305 |

- |

≤320 |

F

E

R

R

I

R

E |

409 |

409 |

A |

≥175 |

≥360 |

≥22 |

≤162 |

≤80 |

≤175 |

| 409L |

409L |

A |

≥175 |

≥360 |

≥25 |

≤162 |

≤80 |

≤175 |

| 410L |

410L |

A |

≥195 |

≥360 |

≥22 |

≤183 |

≤88 |

≤200 |

| 430LX |

430LX |

A |

≥175 |

≥360 |

≥22 |

≤183 |

≤88 |

≤200 |

| 430 |

430 |

A |

≥205 |

≥450 |

≥22 |

≤183 |

≤88 |

≤200 |

| 430Ti |

430Ti |

A |

≥205 |

≥420 |

≥25 |

≤162 |

≤80 |

≤175 |

| 430J1L |

430J1L |

A |

≥205 |

≥390 |

≥22 |

≤192 |

≤90 |

≤200 |

| - |

439M |

A |

≥205 |

≥400 |

≥22 |

≤192 |

≤90 |

≤200 |

| 436L |

436L |

A |

≥245 |

≥410 |

≥20 |

≤217 |

≤96 |

≤230 |

| 444 |

444 |

A |

≥245 |

≥410 |

≥20 |

≤217 |

≤96 |

≤230 |

| 445 |

445 |

A |

≥245 |

≥410 |

≥20 |

- |

- |

≤230 |

| - |

446M |

A |

≥275 |

≥510 |

≥20 |

≤201 |

≤95 |

≤210 |

MARTEN

SITE |

410 |

410 |

A |

≥205 |

≥450 |

≥20 |

≤201 |

≤93 |

≤210 |

| 420J1 |

420J1 |

A |

≥225 |

≥520 |

≥18 |

≤223 |

≤97 |

≤234 |

| 420J2 |

420J2 |

A |

≥225 |

≥540 |

≥18 |

≤235 |

≤99 |

≤247 |

|

| |

Physical Properties & Similer Specificarions Physical Properties & Similer Specificarions |

| Classification |

Grade |

Physical Properties |

Similar Specifications |

| KS(JIS) |

POSCO |

J/g℃ |

Elastic Coefficient

x103N/㎟ |

Thermal Expansion Coefficient

x10-6㎝/㎝/℃

(20~100℃) |

Thermal Conductivity

W/mㆍ℃

(100℃) |

UNS |

AISI |

DIN |

A

U

S

T

E

N

I

T

E |

301 |

301 |

0.50 |

194 |

16.9 |

16.3 |

S30100 |

301 |

X12CrNi 17 7 |

| 301L |

301L |

0.50 |

194 |

16.9 |

16.3 |

|

|

X2CrNi 18 7 |

| 304 |

304 |

0.50 |

194 |

17.3 |

16.3 |

S30400 |

304 |

X5CrNi 18 10 |

| 304J1 |

304J1 |

0.50 |

194 |

17.3 |

16.3 |

|

|

|

| 304L |

304L |

0.50 |

194 |

17.3 |

16.3 |

S30403 |

304L |

X2CrNi 19 11 |

| 304N1 |

304N1 |

0.50 |

194 |

17.3 |

16.3 |

S30451 |

304N |

|

| 304N2 |

304N2 |

0.50 |

194 |

17.3 |

16.3 |

S30452 |

|

|

| 305 |

305 |

0.50 |

193 |

17.2 |

16.3 |

S30500 |

305 |

X5CrNi 18 12 |

| - |

305EG |

0.50 |

193 |

17.2 |

16.3 |

S30500 |

305 |

|

| 309S |

309S |

0.50 |

193 |

14.9 |

13.8 |

S30908 |

309S |

|

| 310S |

310S |

0.50 |

200 |

15.9 |

14.2 |

S301008 |

301S |

|

| 316 |

316 |

0.50 |

194 |

16.0 |

16.3 |

S301600 |

316 |

X5CrNiMo 17 12 2

X5CrNiMo 17 13 3 |

| 316L |

316L |

0.50 |

193 |

16.0 |

16.3 |

S31603 |

316L |

X2CrNiMo 17 13 2

X2CrNiMo 17 14 3 |

| 321 |

321 |

0.50 |

194 |

16.7 |

16.1 |

S32100 |

321 |

X6CrNiTi 18 10 |

| XM15J1 |

XM15J1 |

- |

- |

- |

- |

S38100 |

- |

|

| DUPLEX |

329J3L |

329J3L |

0.48 |

200 |

11.5 |

16.2 |

S32950 |

329 |

|

F

E

R

R

I

R

E |

409 |

409 |

0.46 |

200 |

6.5 |

24.9 |

S40900 |

409 |

|

| 409L |

409L |

0.46 |

200 |

11.7 |

24.9 |

|

|

|

| 410L |

410L |

0.46 |

200 |

9.9 |

25.1 |

S41008 |

410S |

|

| 430LX |

430LX |

0.46 |

196 |

10.5 |

26.4 |

|

|

|

| 430 |

430 |

0.46 |

200 |

10.4 |

26.4 |

S43000 |

430 |

X6Cr 17 |

| 430Ti |

430Ti |

|

|

11.5 |

|

|

|

|

| 430J1L |

430J1L |

0.46 |

200 |

10.4 |

25.0 |

|

|

|

| - |

439M |

0.46 |

200 |

10.5 |

26.4 |

|

|

|

| 436L |

436L |

0.46 |

200 |

10.4 |

25.0 |

S43600 |

436 |

|

| 444 |

444 |

0.46 |

206 |

10.4 |

25.9 |

S44400 |

444 |

|

| 445 |

445 |

|

200 |

10.0 |

|

|

|

|

| - |

446M |

0.43 |

200 |

9.9 |

20.9 |

S44627 |

446 |

|

| MARTEN SITE |

410 |

410 |

0.46 |

202 |

9.9 |

24.9 |

S41000 |

410 |

X10Cr 13 |

| 420J1 |

420J1 |

0.46 |

202 |

10.3 |

23.8 |

S42000 |

420 |

X10Cr 13 |

| 420J2 |

420J2 |

0.46 |

202 |

10.3 |

23.8 |

S42000 |

420S |

X10Cr 13 |

|

| |

Wilding Zone & Quality Wilding Zone & Quality |

| Classification |

Outside bead removal |

Inside & Outside Bead Removal |

Inside & Outside Welding |

Drawing Tube |

| Shapes of Welding Zone |

|

|

|

|

| Characteristics |

Ordinary pipe manufactured by the Tig, plasma welding |

Inside bead remove cold rolling |

Inside & Outside Welding at the same time |

High quality tube by Inside & Outside drawing |

| Production Process |

Forming

↓

Welding

↓

Annealing

↓

Straightening

↓

End-Facing

↓

Pickling |

Forming

↓

Welding

↓

Inside Bead Rolling

↓

Annealing

↓

Straightening

↓

Cutting

↓

End-Facing

↓

Pickling

|

Forming

↓

Inside & Outside Welding

↓

Annealing

↓

Straightening

↓

End-Facing

↓

Pickling |

Forming

↓

Welding

↓

Annealing

↓

Cold Drawing

↓

Degreasing

↓

Annealing

↓

Straightening

↓

End-Facing

↓

Pickling |

| Applications |

For General piping material and boiler, heat exchanger |

For Sanitary boiler, heat exchanger |

For general piping material, fittings |

For boiler,

heat exchanger,

machine structural |

|

| |

|